HOW LEAN IS TOO LEAN

My company has been trying to incorporate various aspects of "lean" manufacturing for the past 6 years, and sometimes it just gets pushed too hard. It's one thing to have everything in it's place. But when the only thing that doesn't have a set location is the employee; things can get a little sticky.

It's true that today's market changes direction quickly, and our businesses must be able to react to those changes; even anticipate them. Our offices, design centers, and factories need to be able to handle multi-tasking, and duel product development in order to keep up with the competition. We need to be able to change gears at a moments notice; drop one product line for another, and incorporate design revisions on a daily basis in order to keep our top clients coming back for more. For these reasons, there is no denying the importance of a lean and agile production environment. If there is old, unusable printing equipment in the back of the press room; get rid of it. If the flow chart shows redundant steps in the process; line them out. These are good things. These things make sense, and I would bet that the majority of your employees would agree. But while we work so hard at ensuring our company's ability to change from one job to another; we sometimes forget how this "mobile philosophy" can impact some, if not all of our employees. This is what needs to be considered when deciding how far you wish to take the lean principals as they pertain to employee's offices.

Employees are most productive when they feel confident. They may feel stressed about a particular task, or concerned about an upcoming deadline. But their resolve to complete their objectives, and their knowledge of how to do this; topped with the companies trust in them, is what gives them confidence. This is what builds passion within a company, and we all know what happens when our employees are passionate about what they do. Six Sigma is undoubtedly a powerful tool that can be used in order to harness this passion. However, tools are only effective when used properly, and in the appropriate setting.

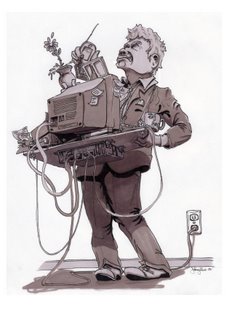

Although lean manufacturing techniques can be very effective on the shop floor, they could prove to be counterproductive if over used in the office area. While your employees are working diligently to incorporate the changes in philosophy these techniques prescribe, they themselves may have reservations to the new concepts that they are working hard to overcome. As they push through the day, putting out one fire after the next, trusting in your vision, and dedication to the new program, the one place where they feel completely in control, is at their desks. Now I agree that a clean work area is crucial to effective productivity, but to have 5s evaluations on the contents of those same desks could defeat all of the progress you have worked so hard to obtain. These assessments could be viewed as a lack of trust from your employees, and when an employee feels as though they are not trusted, they will inevitably loose confidence. Having overall evaluations of the area is obvious. The office needs to be functional, and clean. Printers, scanners, and copiers need to be effectively located for the optimum performance and ease of use. However, the staff needs to feel empowered, and trusted.

As a company, you are hired by your clients based on your qualifications, proven track record, and perceived ability to perform the job. In order to get hired, you put together a comprehensive plan of how to fulfill your clients needs with respect to quality, schedule, and cost. Then, hopefully, they step back, and let you do what you do best. Sometimes we need to remember why we hired our own people in the first place; then step back, and let them do what they do best.

0 Comments:

Post a Comment

<< Home